Our production process

In the video we talk about our production process, all the stages of our daily work to spread out well-being to our people, our customers and the environment.

Join us on a journey that begins with the recycling of aluminium from processing scraps, a cycle that we have incorporated into our facilities and into our production chain.

You will be fascinated by the production cycle of our foundry, where aluminium billets are melted down to extrusion of the profiles, which in a later stage are painted with solvent- and heavy metal-free powders.

For the chrome plating of both aluminium and plastic profiles, we are the only European manufacturer using PVD (Physical Vapor Deposition) technology, a chrome plating process without hexavalent chromium or carcinogenic chemicals.

We also pay the utmost attention to the " endless" processing of glass, which in the final screen-printing and decoration process sees the use of water-based, solvent-free and lead-free decorations.

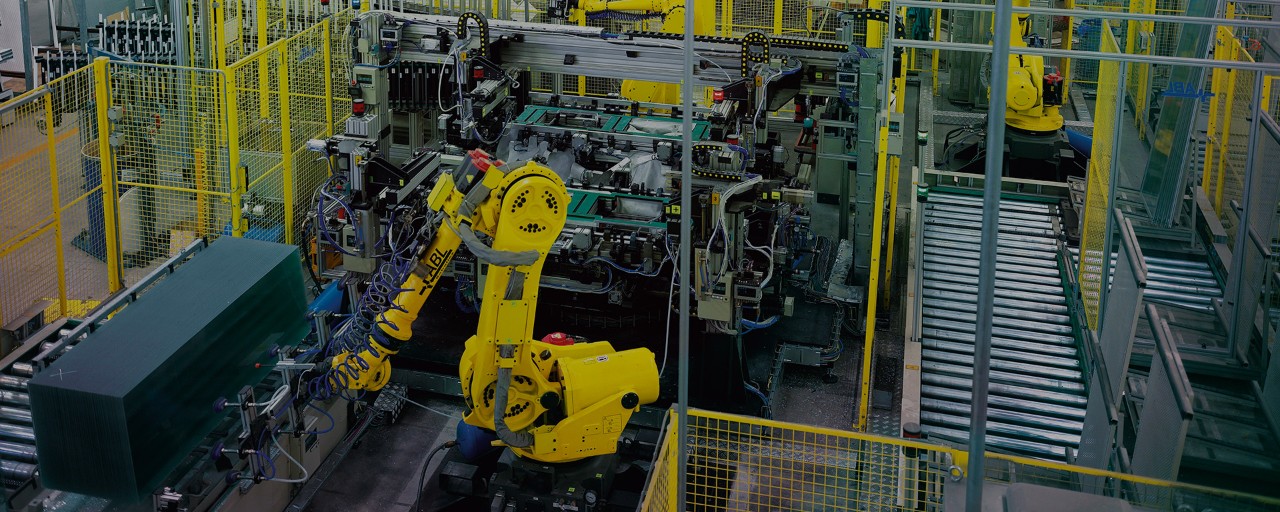

Man/machine synergy guides all the final processes: from resin coating to painting, from the assembly of shower enclosures and cabins to the testing of whirlpool baths.

We leave nothing to chance, not even when it comes to packaging. We only use cardboard and recycled polyethylene, and the design of our boxes facilitates waste separation.

A fascinating tale that ends at our high-tech warehouse, our little jewel of automation.